How Long Does It Take To Repair Browning Trail Camera Repairs

Most trail cameras work most of the fourth dimension. However, the outdoor surroundings is hard on electronics and some fail. In this post, I review the record of cameras we have used over the years to give an business relationship of symptoms, failure modes, and in virtually cases, fixes. Perhaps this will assist you figure out what'south wrong with an out-of-warranty photographic camera. Even better, if trail photographic camera manufacturers could take this data to heart, perchance they could eliminate these failure modes from future models!

[Updated 2022-07-19] Added "Disassembly Notes" section at the terminate of this post with tips on taking some cameras apart.

Overview of Failures

| Name | Symptoms | Failure | Fix |

| Stuck IR Filter | Pink day photos; dark night photos | Cold solder joint on leads for IR filter motor | Reflow solder on IR filter motor leads |

| Run-On Triggering | Multiple videos with no animal later legitimate trigger | Thermal path between CPU and PIR detector causes cocky-triggering | Increase delay between triggers; push PIR detector one mm upwards off surface of PCB; tighten CPU heat sink screws |

| Loss of Focus | Over time, photos and videos become blurry and out of focus | Failure of lens, which sometime seem to develop an "astigmatism" (areas that our out of focus) over time | Supervene upon the epitome sensor lens |

| Early Bombardment Draining | New batteries fail after a few weeks in the field | Corrosion of pocket-size internal battery leads to college than normal electric current drain while photographic camera is in "sleep" manner | Remove corroded battery, clean PCB, supersede with a new prison cell. |

| Reset Date/Time | Date/Time reset to some default (e.grand. 12:00, January-ane, 2022) despite existence recently set | Wearout of the small internal battery prevents real time clock from working | Remove discharged battery, replace with a new prison cell. |

| Lost Time | Fourth dimension is off by an 60 minutes or more, despite beingness recently gear up | Unknown | Unknown |

| Punctured PIR Lens | PIR sensor stops working; h2o incursion; visible damage to PIR lens | Thin Fresnel lens over PIR sensor is punctured or cleaved, often by a bird pecking at it; sometimes by a large tooth | Supersede Fresnel Lens with replacement from manufacturer |

| Wink Failure | Dark night shots; IR Flash does non come up on | Drive transistor for high current IR LED array overheats, melting plastic, opening excursion | Supplant bulldoze transistor if possible. If plastic is damaged, time to retire camera |

| No Photos Taken | Despite new batteries, working SD card, correct settings, right arming, camera takes no photos/videos | Unknown | Unknown |

| Water Incursion | Moisture or condensation visible on the inside of the camera, often in front of photographic camera lens, or LED flash window | Design limitation; failure of gasket systems; crevice in Fresnel lens for PIR sensor. | Design problems may not be repairable. Check all gaskets for integrity and proper seals. Check Fresnel lens and supervene upon if cracked. |

| SD Card Failure | Camera will not plough on, or freezes, or does not take photos or videos, or runs downwards batteries in <24 hours | SD menu is unreadable, unwritable, or returns errors to firmware which cannot be handled | Discard SD card and supervene upon with ane that works |

Stuck IR Filter

Many cameras use a motor-driven IR filter to block out IR during daytime photos, while allowing IR to get to the sensor for night time photos. If the IR filter is working, you lot can hear a faint "click" as a tiny, simplified, electrical motor moves the IR filter from ane stable position to some other, and back.

Symptoms of Stuck IR Filter

Failures of the IR filter result in 2 kinds of "wrong" photos/videos:

- If the IR filter becomes stuck while disengaged (non roofing the lens and image sensor), nighttime photos volition be fine, but daytime photos will be pink. This is because the image sensor is interprets the IR from the lord's day as "extra" red. This is the problem with the pinkish panther in the intro photo.

- If the IR filter gets stuck while it is engaged (over the lens and image sensor), daytime photos will be fine, merely dark photos will be very dark, because the stuck IR filter is preventing IR light from the flash from getting in. This is sometimes misinterpreted as a failed flash unit. Information technology can be differentiated from this case if the flash itself is actually coming on during night shots.

The IR filter is frequently the only moving part in a trail photographic camera, and therefore subject, in principle, to mechanical failure. Some manufacturers even go then far as to offer models with 2 image sensors — 1 with an IR filter, and 1 without — in part to avoid the possibility of IR filter failure.

Debugging Stuck IR Filter

False Lead: It's not the mechanical part!

In debugging these cameras, my initial hypothesis was some sort of mechanical failure of the motor system. On investigation, I found that the motor mechanism is refreshingly unproblematic and robust. In all cases of "stuck filters" I investigated, the IR filter mechanism showed every sign of working correctly, equally shown in video below.

The Real Culprit: A Cold Solder Joint

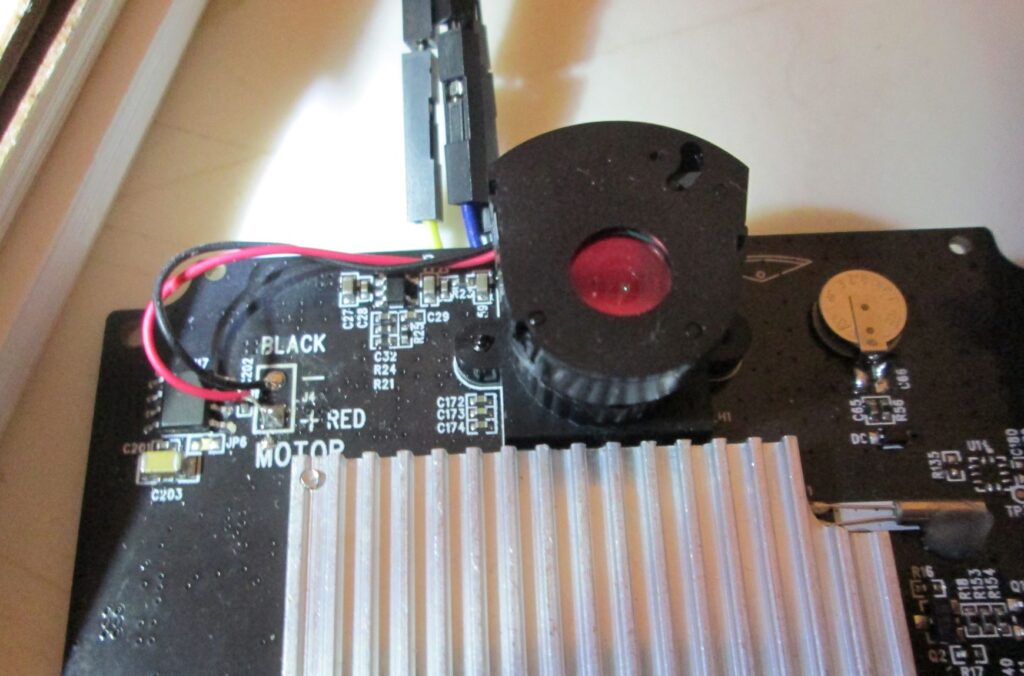

Instead, the problem has been a common cold solder joint betwixt the wires from the primary PCB to the IR filter motor. Cold solder joints occur when the solder doesn't quite get hot enough to melt completely. The connection tin can await good, and even piece of work well for a while. Over fourth dimension, yet, the connection fails, eventually leading to a sometimes intermittent open excursion. Cold solder joints have a notorious history, but accept largely been eliminated past automation from modern, mass-produced electronics. I believe they occur in some trail cameras because of transmission soldering of the IR filter motor wires to the PCB, and considering at least 1 of the PCB pads dissipates a lot of heat, and is therefore more hard and time-consuming to solder correctly.

Fixing Stuck IR Filter

One can sometimes "fix" a cold solder joint past mechanical agitation. Yes. By "banging information technology." Unfortunately, the trouble is likely to recur equally thermal changes and oxidation work their undesired magic. The permanent solution is to open the camera and to utilise a soldering iron to reflow the solder on the offending joints. Nowadays, I need a magnifying glass (or better, a binocular dissecting microscope) to sentry the satisfying signal at which the solder melts into a uniformly shimmering mass and wicks completely around the pad on the circuit board and the wire to the IR filter motor.

Run-on Triggering

Symptoms of Run-on Triggering

This is a trouble I accept seen in several cameras. I even featured one of these failure modes, in which a photographic camera suddenly "photos itself to (battery) death" in an before post. Run into: Runaway Trail Camera. I have recently seen a variant of this problem in Browning models BTC-7A and 8A. The photographic camera takes a video on a legitimate trigger, but then continues to take videos constantly for up to several minutes. This even though the beast has long left. We have seen this failure develop in cameras over fourth dimension. That is, initially the camera operates correctly, but over time, it begins to become more and more of these "run-on" trigger events.

Debugging Run-on Triggering

After some investigation, I believe this trouble is caused by unwanted coupling of oestrus betwixt the microprocessor (used to process the video and compress it into MPEG files) and the PIR sensor. As cameras become smaller, designers are more likely to put the heat-generating processor closer to the highly rut sensitive PIR sensor. This at the same time they are using increasingly sensitive PIR sensors (to capture all those animals!) , and processing higher resolution videos (generating more heat from the microprocessor). The PIR sensor is sensitive to changes in its local temperature, which tin can cause it to trigger falsely.

In the scenario I have documented in the lab, the processor heats up while processing the outset video. Then the heat from the processor travels through the PCB to the PIR sensor. The PIR sensor starts becoming warmer at a rate that exceeds two degrees Celsius per minute (the rated maximum spec on the PIR sensor). This causes the PIR sensor to immediately trigger, which causes the processor to go even hotter, and so information technology goes. Fortunately, the PIR sensor is only sensitive the the rate of modify of its ambient temperature. Once the the sensor reaches an equilibrium temperature, it stops triggering, and the run-on stops.

I think the root causes of the problem are some combination of:

- bereft margin in the thermal design of the photographic camera

- a possible design or manufacturing error in which the PIR sensor is placed flush with (and therefore in tight thermal contact with) the PCB

- failure of the the thermal bail betwixt the processor an the rut sink, causing PCB, and with it the nearby PIR sensor, to get hotter

Update 2022-11-10: We noticed that this problem seems more common in Browning Spec Ops Advantage (BTC-8A) vs. Recon Force Advantage. Turns out that the BTC-7A has a series of cutouts in the PCB around the PIR sensor which limit heat period (see photograph to a higher place). The (earlier?) BTC-8A PCB does not accept these cutouts. Increased heat flow through the PCB in these cameras explains the increased prevalence of this problem.

Fixing the Problem

I can work-around this problem by setting the "Photo Delay" parameter (the minimum amount of time the photographic camera will wait before re-arming) to be larger. This allows the camera to cool downwards a petty before waiting on the PIR sensor. Unfortunately, this also means that the photographic camera won't retrigger quickly if the animal is still there.

I accept had some success in reducing (if non completely eliminating) the trouble by:

- tightening the screws which help hold the heat sink in contact with the processor. This allows more of the heat generated by the processor to exist prodigal past the heat sink, reducing the heat menstruum through the PCB, and ultimately to the PIR sensor.

- unsoldering the PIR sensor; pushing it up off the PCB by a millimeter or so, and resoldering. This increases the thermal resistance between the PCB and the PIR sensor, thus reducing heat transfer.

Loss of Focus/Photo/Video Clarity

Symptoms of Loss of Focus

I have seen this problem now in several Browning models (e.grand. the Recon Strength Farthermost BTC-7FHD-PX, and the newer Recon Force Edge BTC-8E), but I expect it to be endemic to exist in other types of cameras as well. Initially, the camera takes nifty, crisp and clear color and nighttime fourth dimension photos and video. However, over time, the quality of the images deteriorates equally both the photos and videos get blurry and out of focus. On careful inspection. one can former see that merely a portion of the prototype is blurry and out of focus.

Debugging Loss of Focus

Afterwards much caput scratching, I came up with a uncomplicated experiment that at least isolated the problem. I took a series of photos of myself at varying distances from the photographic camera, with and without a "cosmetic" magnifying lens from a pair of reading glasses taped in front of the photographic camera's own lens. I plant that in all the photos without the corrective optics, the photos were blurry and out of focus. However, for some of the photos taken with the cosmetic lens, the photos were in perfect focus.

The fact that the cosmetic lens stock-still some of the photos ruled out whatsoever problem with firmware or processing hardware. More subtly, it ruled out the possibility of lens condign scratched, cloudy, or possibly covered with condensate.

This problem remained mysterious to me considering the "fixed focus" plastic lens mount and lens seemed and so solid. Not so.

Details on the Lens Assembly

As shown in the photograph below, the "stock-still" lens associates is actually two pieces. The beginning piece is a Type-S, or "M12" lens mountain, which attaches to the PCB with a pair of screws. The lens mountain has a 12 mm hole, tapped with a 0.five mm pitch ready of threads. A small lens screws into these threads. The corporeality that the lens is screwed-in determines its distance to the sensor, and therefore the optical focus.

A Theory Revised

My original theory was that the lens was somehow rotating in the mount (possibly due to improperly installed glue), causing the photographic camera to lose focus.

Subscribers to the blog (cheers Ulli and Dan!) had this trouble and agreed to exam out my early on theory. They institute that the glue was solid. Moreover, that since the IR Filter motor is stuck to front end of the lens, and it had not rotated, neither could the lens. Finally, when they turned the lens (a good half plow) they found that it fixed the focus in one part of the paradigm, but fabricated it worse in other parts of the epitome.

This new data required a new theory, and here it is: the lens itself is deteriorates over time. This is not surprising, given the number of thermal cycles these cameras often feel, and the low-cost, plastic housing for the lens components. I'1000 imagining that the lens assembly somehow goes a piffling out of alignment, causing the image to go defocused. I accept verified, in any instance, that replacing the lens fixes the problem.

Fixing Loss of Focus

This repair requires replacing the image sensor lens. In the repair I did, I used a lens from a "parts camera" equally a replacment. I am currently working on a post that includes sources for replacement lenses. Until so, I would not recommend simply buying an S-type, M12 "compatible" lens every bit a replacement. Trail cameras seem to rely on a unusually compact lenses, and most of the lenses I've found on line are too long, and won't fit in the photographic camera. Stay tuned.

The repair involves getting into the camera, removing the primary circuit board, removing the IR filter motor assembly from the height of the lens (it'due south held on by double sticky tape). I replaced the whole lens mount/lens assembly, merely it's possible to but change the lens. The latter requires removing the glue forth the threads. Dan advises the use of modest screw driver heated with a flame to soften the mucilage. Future postal service will include details on setting the focus correctly.

Early Battery Bleed

Symptoms of Early Bombardment Drain

Occasionally, cameras seem to drain batteries very quickly. This whether they are taking photos and videos or non. A modern trail camera should have tens of thousands of photos and several hours of video, fifty-fifty at nighttime with the flash, on a new set of AA Energizer Ultimate Lithium batteries. It should last in the field without taking videos or photos (merely waiting, with the PIR sensor active) for years.

We recently ran across this problem after a long hiatus when retrieving a "pandemic" camera that had been in the field for over a twelvemonth. Unfortunately, this Browning Strike Force Hard disk Pro (BTC-5HDP), with a new prepare of six Analeptic Ultimate Lithium batteries exhausted its batteries, somehow, later on less than a month. This was particularly frustrating, since it was in a actually skilful spot! During the calendar month information technology worked, information technology got some great photos, and would take undoubtedly gotten many more had it not failed. The silver lining is that I got to investigate this failure mode in particular.

Debugging Early on Bombardment Bleed: Typical Trail Photographic camera Operating Current

Trail cameras consume ability in ii ways: while taking video or photos; and while waiting to take video or photo. Actually taking the the photos/videos consumes much more power than simply waiting. In this camera — the agile power is about 650 mW, whereas the "sleeping" ability is shut to 650 uW — or 1000 times less.

The photographic camera in question used the batteries at greater than 60 times the expected rate. This is very difficult to exercise in the agile state — since consuming ~lx times the power is difficult to do with the available components, fifty-fifty in failure. This caused me to suspect the "sleeping" power. Since this power is very low to start with, there are several possible failure modes which could swallow little absolute ability, just notwithstanding much more the intended idle power. Since idle power is consumed all the time, fifty-fifty a minor amount can drain the batteries over a series of days or weeks.

I used my digital multimeter to measured the current (which is proportional to power) consumed by the problem camera. I happened to have (from the aforementioned trip) a camera of the same model that had not failed, which I was able to utilise equally a reference. I confirmed that the electric current (ability) consumed past both cameras in "active" modes — that is taking photos and videos, or displaying the user interface — was very close.

And then I moved on to the "sleep" mode and found some strange beliefs in the trouble camera. Unlike the good photographic camera, which consumed a abiding ~50 uA, the trouble camera started out consuming three times this corporeality. Over time, information technology seemed to approach the lower effigy, simply the long time abiding (10's of minutes) suggested some energy storage element — a capacitor or perhaps battery — was non working properly.

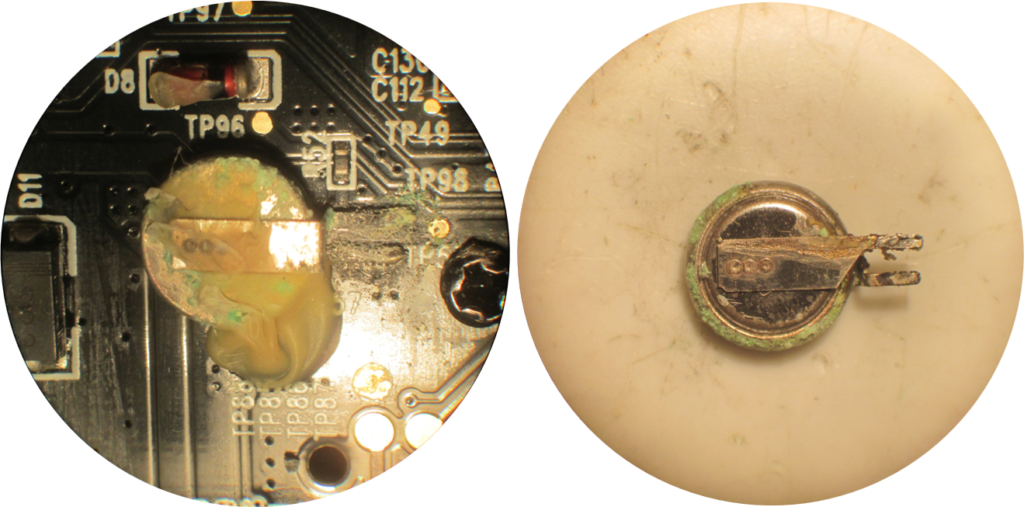

On visual inspection, I found a pocket-sized bombardment on the PCB with some corrosion between the positive and negative leads. This battery is used to power the existent-time-clock (RTC) (appointment and time) device while the user is changing the main battery pack. This bombardment is designed to exist "trickle charged" at a very low current (< 10 uA), and tin power the RTC for several hours.

In the example of the failed camera, some bit of moisture lead to corrosion betwixt the positive and negative bombardment pins. Alternatively, the battery itself failed due to thermal cycling, and started to leak. Whatsoever its source, the corrosive mixture created a parasitic circuit between the battery pins. This "short" drained the battery and caused the charging circuit to try to draw more than current as it tried to charge the small battery from the main battery pack. After 30 days of doing this, the master battery pack was completely drained. Diabolically, in the intervening year, the corrosive mixture dried out and became less conductive, masking the original failure manner.

Fixing Early Battery Drain

I was able to observe a like, 3V, rechargeable, surface mount bombardment online (encounter references) — the Seiko MS920T-FL27E for a couple dollars. It is slightly larger than the original jail cell, only none-the-less fits on the PCB, and has a uniform set of pads. I removed the erstwhile battery using some solder wick, cleaned upwards the board, and and then installed the new battery. The current draw in "sleep" is now back around ~50 uA, and the new battery maintains the RTC while I'm swapping the primary battery pack.

Reset of Engagement/Time

Symptoms of Reset of Appointment/Fourth dimension:

Appointment and time on camera are incorrect, appearing as the pre-prepare default (e.thou. 12:00 am, Jan-1, 2022) , even after being properly gear up. Depending on the type of camera, the data and time may go amiss only during changes of the chief battery pack, or even with the main battery pack installed (and charged). This problem ordinarily develops later cameras take been used for several years.

Debugging Reset of Appointment/Time:

Verifying this trouble is done by opening the camera and measuring the voltage across the 2 terminals of the internal battery. Encounter photos in "Early Battery Drain" section, above, for an example of what these batteries can look like. Assuming a 3 Volt battery, a measurement below ~2.7 Volts indicates battery is discharged.

Cause of Reset of Date/Time

In addition to the main battery pack, most trail cameras have a small-scale internal battery permanently mounted on the PCB. This bombardment provides continuous power to an ultra low ability "real time clock scrap." In some cameras, this battery is rechargeable, taking a trickle charge from the main battery pack. In other cameras, the battery is not rechargeable. In either example, failure of the internal battery (either due to charge/discharge cycles, or just running out of power), removes power from the real fourth dimension clock scrap, causing the camera firmware to revert to the default, preset value.

It is possible that farthermost temperature fluctuations, hot or cold, may lead to early failure of the small internal battery.

Fixing Reset of Date/Time

This problem can be resolved by replacing the battery on the PCB. This procedure is the same every bit described in, "loftier battery consumption." The outset, and almost important footstep is to discover a proper replacement bombardment. A non-rechargeable battery should never be used equally a replacement for a rechargeable battery. Unfortunately, I do not have samples from plenty cameras to list bombardment types. Ideally, the bombardment will be marked with a manufacturer function number.

If the battery is not labeled, at that place are other means to make up one's mind whether the battery is chargeable, or not, and the nominal voltage.

The failure style tin can provide insight into the battery type. If the photographic camera loses rail of date/time even when principal batteries are installed and charged, there is good chance that the RTC bombardment is non rechargeable.

Alternatively, if it only loses date/time when primary batteries are removed, it is likely rechargeable. To exist sure, use a mulitmeter to mensurate the battery voltage with and without the master batteries installed. If the voltage goes up when the main batteries are installed, the internal battery is likely rechargeable blazon.

I have simply found iii Volt batteries in the trail cameras I've looked at, but this is no guarantee (and may change over time – this post written in 2022). For cameras which recharge the internal bombardment, measuring voltage across battery terminals with the primary batteries installed will testify slightly above the nominal voltage. Unfortunately, measuring a dead bombardment won't tell you what the charged voltage should be.

Lost Time

Symptoms of Lost Fourth dimension

This failure is similar to "Reset of Date/Time" failure in the date and fourth dimension are incorrect. Still, in this failure way, the date and time are only "off" by a number of hours, vs. resetting to a manufactory default value. And so far, nosotros take but observed cameras losing several hours, never gaining hours. Note that the time beingness off by a small number of minutes over the same period is a "characteristic" of the bombardment-powered RTC design, which accrues some drift in its internal time base.

Debugging Failed Flash

I am still in in the process of collecting data on this failure mode, which happens in our sets relatively rarely. Here are some questions I'g trying to respond:

- Does the loss of time occur in detached events or as continuous, gradual slowing of the rate of incrementing?

- Assuming errors occur in discrete events, is there any correlation in the "time" at which these events occur in a population of failures?

- Assuming errors occur in detached events, are they associated with any environmental anomalies (e.g. much higher or lower temperature)

- Having lost time once, does the photographic camera ever spontaneously get the right fourth dimension dorsum once again (without beingness reset)?

- Having lost time once, is a particular camera prone to losing time in the future?

If you lot have answers to any of these, please respond in comments, below!

Broken PIR Sensor Lens

Symptoms of Broken PIR Sensor Lens

Usually damage to the PIR sensor lens is obvious on inspection, and may involve other cosmetic damage to the camera. These sparse pieces of plastic can exist punctured by birds, or by the teeth of animals. They may besides get breakable and crack on extended exposure to directly sunlight due to UV damage.

If damage is more subtle, you may starting time notice poor PIR sensor performance and/or moisture in the camera.

If lens is damaged, it's important to take your camera out of service ASAP, as water tin hands leak in and crusade more (perhaps irreparable) damage. Hopefully, you grab this trouble before that!

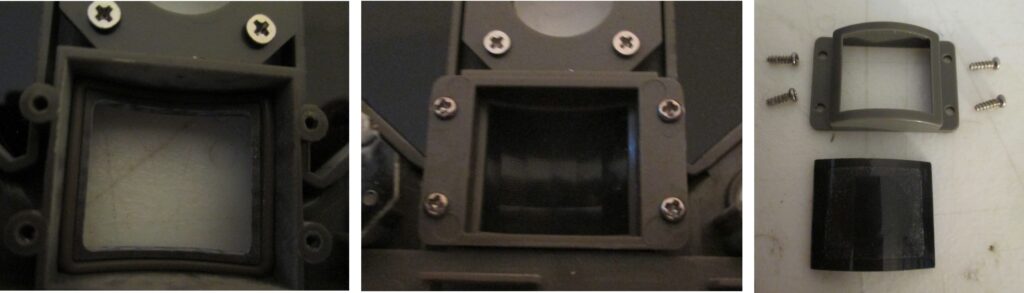

Fixing Broken PIR Sensor Lens

Fortunately, several manufacturers, including Browning (come across References) offering replacments for broken PIR sensor lenses. Find and order a replacement and follow manufacturers instructions for replacing. Y'all volition demand to disassemble the camera to get at internal fasteners and gasket. Photo beneath shows a typical seating mechanism for the PIR lens. Annotation that the PIR lens is highly engineered. It features an assortment of Fresnel lenses in a very particular orientation and a camera-specific focal length. Your best bet is a manufacturer replacement for your camera. A part from another manufacturer may work on your camera. A piece of black plastic is right out 🙂

Failed Flash

Symptoms of a Failed Flash

I've just seen this trouble in older Moultrie model. The flash stopped working, and the dark photos were very dark or completely black. I determined that the IR LEDs were not working by testing the camera in a dark room, and looking for a faint red glow from the IR LEDs. Alternatively, yous can take advantage of the IR sensitivity of most digital cameras to test for IR light by looking at the camera nether examination through the camera viewfinder screen. It likewise helps to accept a working trail camera to compare to.

Debugging Failed Flash

When I opened up the photographic camera, I could encounter that the ability transistor driving the LED array had gotten so hot that information technology had melted the plastic housing for LED PCB, and then failed at some point.

Fixing Failed Wink

I might accept solved the problem by replacing the flash PCB. Unfortunately, the melted plastic kept a new PCB from fitting into identify, so I ended up turning this unit of measurement into a "parts photographic camera".

Water Incursion

Symptoms "Water Incursion"

Water, or more typically wet, can sometimes find its way inside the camera. Symptoms include visible condensation on *inside* surfaces. The can include the inside of the camera window, or inside surface of the Flash LED window. Moisture tin also damage sensitive electronics, also as crusade corrosion of connections. Suspect water damage if the operation of the photographic camera seems flaky: card cuts out; camera spontaneously resets itself; and specially some combination of apparently unrelated symptoms.

Debugging "H2o Incursion"

"All" y'all have to do is effigy out where the moisture is getting in, and fix information technology. Here are things I would cheque. The details vary by camera type. I've used a Browning Recon Force Advantage (BTC-7A) as a specific example

- Fresnel Lens for PIR Sensor: can become cracked over time.

There are 5 sets of "gaskets" on the BTC-7A that I'm aware of:

- The rubber plugs that seal each of the half dozen recessed holes for the screws which agree the forepart and dorsum case pieces together

- The gasket that seals the battery compartment. This is on the case, effectually the slot where the battery carrier snaps in

- The gasket that seals the the fold-out door.

- The gasket between the forepart and back housing pieces. This ~1mm piece of rubber get sandwiched between the housing pieces.

- The gasket effectually the Fresnel lens/window for the PIR sensor. Getting at this requires taking the main circuit board out, every bit well as the Flash LED board, to expose a plastic piece held in by 4 screws. While this out, have the opportunity to double check the integrity of the Fresnel lens. See photos in "Broken PIR Sensor Lens"

Check that all of these are clean, undamaged, and properly fitted.

If a conscientious visual inspection doesn't turn upwards any source of leak, y'all may have to resort to some variant of the "dunk" examination. For instance, on one of my homebrew DSLR enclosures, I "floated" (simply) the front plate (including the barrel and window for the main photographic camera) in a pot of water. Certain enough, subsequently a couple of minutes, I found sources of leaks. I haven't done this with i of the commercial cameras, but, in principle, I tin can imagine removing enough of the camera innards to be able to "float" the lesser and meridian cases. If you do this, brand sure that there are no electronics to batteries to get wet if h2o gets through.

Fixing "H2o Incursion"

With luck, a problem with a gasket can be fixed past cleaning and/or resetting the trouble gasket. Missing hole plugs for the BTC-7A tin be replaced as in my post Inside the Browning Recon Strength Aristocracy HP4 (BTC-7E-HP4). Note that not all cameras crave these. If a gasket has been permanently damaged, replacement is the merely choice. I accept used the online O-Ring Store as a source for O-rings of the type plant sealing the Fresnel lens. You'll have to measure the size yourself. If you take this path, I recommend "bracketing" the size with slightly smaller and slightly larger replacements to increase the chance you lot have something that works.

In the absence of a replacment, you may exist able to brand do with a small-scale, continuous bead of silicone caulk. Washed caerefully, this is as skillful as a gasket in sealing the front and back enclosure halves. It does brand time to come disassembly more difficult, and volition require replacement on reassembly.

Finally, if all else fails, for "mild" moisture incursion, you tin can use silica gel packs to soak up wet that does go in. This solution is relatively easy to apply to a typical homebrew cameras. Unfortunately, there's typically not a lot of infinite inside a commercial trail cameras for "extra stuff." Putting them within the case is problematic because it requires opening the case to replace them (and they do demand to be replaced and re-dessicated to remain effective). Somewhere in the battery compartment, maybe double-sticky taped to the back of the battery tray? Inventiveness required.

If your camera is malfunctioning after a water "incident" you may be able to repair. Offset by visually inspecting the circuit boards for signs of corrosion and h2o harm. If you find these, use a cotton-tipped swab and some isopropyl booze to gently make clean the corrosion from the lath. Pay special attention to the internal coin cell battery used to maintain the real-time-clock (see "Early Battery Drain" section in this post).

Unfortunately, some water harm may to irreparable harm to the excursion board and/or components.

No Photos Taken

Symptoms of "No Photos Taken"

A problem (so far) for the mystery bin. In these cases, we prepare the photographic camera, following a checkoff list which includes verifying that:

- the camera has good batteries,

- the camera powers on

- the LCD comes on

- the camera has initiated its "countdown" to automatic triggering.

- the SD card is relatively new, and has been formatted in the photographic camera — typically right before arming it in the field

None-the-less, when we return, weeks subsequently, total of expectation, we discover that the camera has taken nil photos. None. Non even of usa finishing the setup. And, yep, the batteries are even so good.

Debugging "No Photos Taken" (a piece of work in progress)

We have experienced this near frustrating blazon of failure several times, primarily on Exodus trail camera models. The problem is intermittent and non reproducible. The SD card is empty, with no files, equally it was afterward existence formatted in the photographic camera before the final arming operation. I have used several disk recovery tools and never found any indication that the photographic camera had written anything new. The SD carte itself is fine. Indeed, after beingness turned off and back on, the same camera (with the aforementioned batteries) can record to the same SD card.

The good news is that this problem happens very rarely. The bad news is that without being able to reproduce it, I have been unable to become to a reliable root crusade. Mayhap an obscure firmware bug or mistake instance in the camera startup sequence? I'one thousand all ears, cyberspace!

SD Card Failure

Despite their small size, SD cards are, themselves, a complex computer system with memory, processing, and a dandy many internal error cases. The firmware inside the SD bill of fare allows the billions of fundamentally unreliable, "storage cells" to announced to the trail camera as a reliable data storage device. Sometimes the errors win.

Symptoms of "SD Card Failure"

- Camera will not turn on: Turning a mod trail photographic camera "on" results in a whole pile of firmware being run before you see the "splash" screen. This code incudes internal checks of the hardware, including the SD carte du jour, to make sure they're working. A failed SD carte can return a fatal error during one of these checks. Such errors happen so early in the software "kick" process that the screen isn't ready to report the mistake (as it does if the SD card is missing completely). The just recourse the firmware has is to turn the photographic camera off and hope that things get better the next time the switch is flipped.

- Camera Freezes: Something similar can happen while camera is reading SD card contents. In this instance, if it gets a fatal error it can't (or isn't programmed to) fix, it may just "freeze" the camera, requiring a reset of the on-off switch, or even removing and replacing the bombardment pack.

- Early Battery Draining: If the camera freezes in the eye of trying to write a video or have a photo, it will not become dorsum to sleep, and will consume as much power equally information technology would if it were taking a video or photo. At this rate, it will draw down a new set of batteries in less than 24 hours. Annotation this is a much faster rate than is caused by a failed internal RTC battery (in a higher place).

Debugging "SD Card Failure"

Considering SD card failure tin be intermittent, good debugging hygiene is required to track downwardly their failure. By this I hateful keeping skillful records of what you changed, and what happened. Certainly, symptoms above propose potential SD card failure. In general, the best practice is to put known-skilful batteries (or an external power supply) to eliminate low battery as a possible problem.

Remove the SD card from the photographic camera and try some other SD bill of fare which you know works. If this fixes the problem, put the onetime SD card back and see if problem comes back. If information technology does, y'all have your culprit.

You lot tin endeavor putting the SD card from the camera with symptoms above into a different camera to see whether the symptoms follow the SD bill of fare. Unfortunatley, I've seen cases where an SD card would (at least appear to) work fine in 1 photographic camera, but non in another, so this may non be a reliable test.

Fixing "SD Card Failure"

It is possible that reformatting a failed SD carte du jour in a PC (long or curt format blazon) volition "repair" a failed SD bill of fare. However, given the opportunity lost in an SD card that fails in the field, and their relatively low price, we have taken to a "i-strike" policy. Whatsoever fourth dimension, including the first fourth dimension, an SD card fails nosotros discard immediately. If you exercise try to recover an SD card by reformatting it, make certain to marker information technology in some way and so that you will know (definitely!) to discard it if it fails twice.

Summary

Have y'all seen these failure modes? Others? Have you tried fixing these problems? Please comment beneath.

Disassembly Notes

Videos

Browning BTC-7A and 8A

I used a hooked dental tool to remove the "safe stoppers" which continue h2o out of the 6 screw holes that hold on the dorsum cover. Once these were out, I used a #one Phillips head screwdriver to remove the screws.

The main PCB is likewise held in place 6 small screws. There are several sets of wires which connect the main PCB to: the battery pack; the front keypad; the microphone; and the IR LED assortment. It's a trivial tight, merely I found that I could get at most of the master PCB without removing any of these past conscientious manipulation of the board. The ribbon cable to front end keypad is connected via a "flip-clamp" connector to PCBs on either end. The flip bar can released with a minor apartment screwdriver to release the cable and give a picayune more working flexibility. The other wires are all soldered to the main PCB.

The two screws for the estrus sink fit directly into tapped holes in the heat sink itself. I found when tightening these screws that it was like shooting fish in a barrel to strip them — an undesired outcome. Information technology may be that the screw in question was already stripped when I got to information technology, which could have been role of the problem. These screws are tiny — smaller than ii mm. I was able to insert a slightly larger spiral (not certain exactly which size, maybe M 1.seven) into the stripped hole and it self-tapped in the soft aluminum of the oestrus sink.

On reassembly, I sometimes plant myself forgetting to re-install the little safety stoppers into the screw holes in the case. This would have been a fault, since these stoppers are part of the gasket system which keeps wet out of the photographic camera.

Lens Assembly and IR Filter

To admission the lens associates (e.g. for "Loss of Focus" ready), the IR filter must be removed. The IR filter is only held on with double sticky tape (!) to the face of the lens assembly. Prying it dorsum and along gently volition loose the adhesive and allow removal. For reassembly, I scraped off the adhesive, applied another piece of double sided record (making certain not to cake the lens!) and stuck information technology back on.

References

- WildLabs camera trouble-shooting database: this conservation tech organization keeps a community spreadsheet where users can report camera failure modes. You may need to annals to view this GoogleDoc.

- Seiko MS920T-FL27E Rechargeable coin Cell Battery with SMT pads: Available at multiple sources, including mouser.com.

- Browning Replacement Parts: PIR Lens

Source: https://winterberrywildlife.ouroneacrefarm.com/2021/06/30/how-some-trail-cameras-fail/

Posted by: dahmsfuriall.blogspot.com

0 Response to "How Long Does It Take To Repair Browning Trail Camera Repairs"

Post a Comment